More Car Makers to Use 3D Printing in Future?

Researchers at Tohoku University’s Institute for Materials Research have made a breakthrough in a multi-material 3D printing. They have demonstrated the process for creating a lightweight yet durable automobile part using both steel and aluminium.

Metal 3D printing involves building objects by depositing metals layer by layer, using heat to bind them. The process can produce unique, highly customisable shapes in environmentally sound fashion.

Using 3D printing ‘multi-material structures’ are fashioned using different materials for optimal performance of a component. Steel car parts may be lightweighted by combining them with aluminum. Therefore, various groups are working to master such 3D printing techniques. Problem is, there are issues with resulting metal strength, primarily because of weakness at the interface of the materials.

Associate Professor Kenta Yamanaka (Tohoku University), said “A major challenge in practical implementation is that for certain metal combinations, such as steel and aluminum, brittle intermetallic compounds can be formed at the dissimilar metal interfaces. So, while the material is now lighter, it ends up being more brittle.”

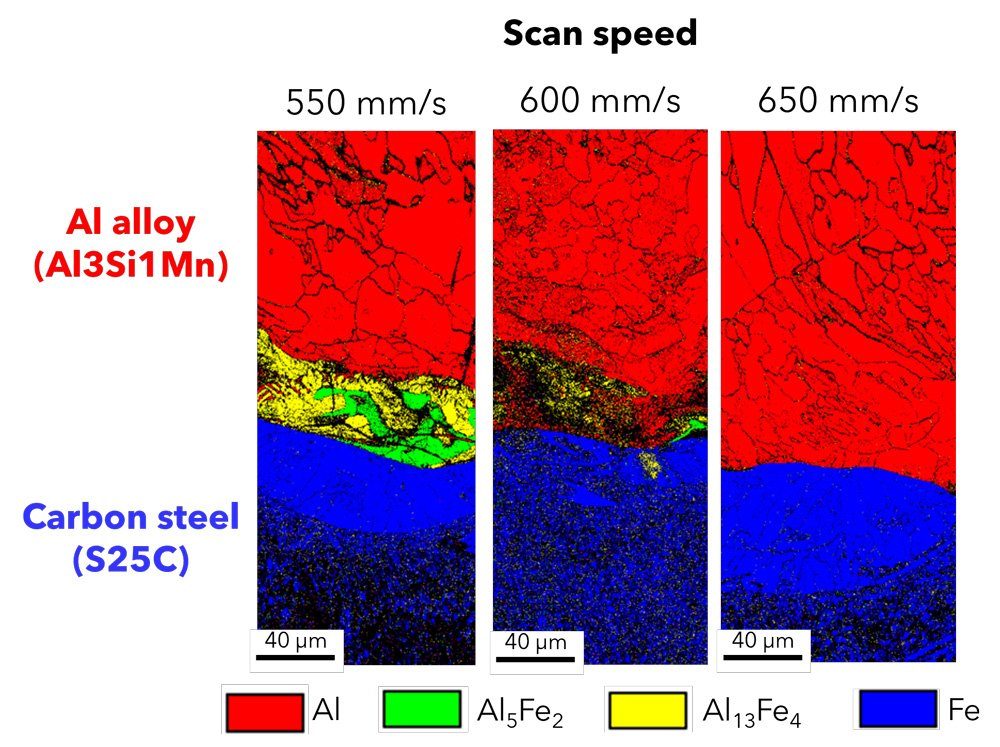

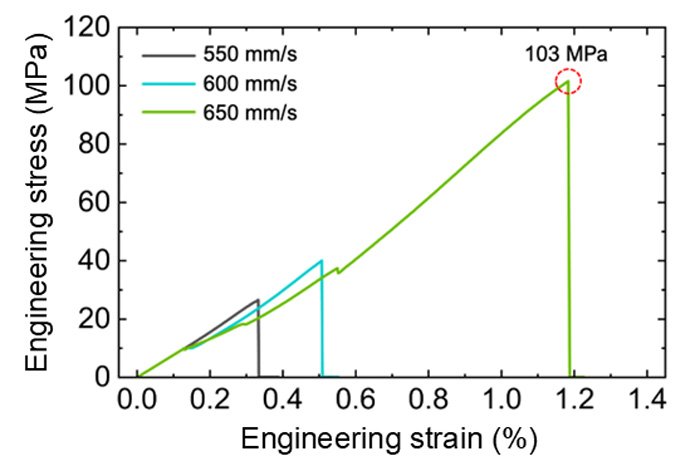

So the aim is to produce a steel-aluminum alloy that is lightweight but strong. To do so, the research team used Laser Powder Bed Fusion (L-PBF), one of the primary metal 3D printing technologies that employs a laser to selectively melt metal powders.

By increasing the scan speed of the laser, they found this significantly suppresses the formation of brittle intermetallic compounds. The higher scanning speed seems to minimise solute partitioning that results in weak points in the material.

“In other words, you can’t just slap two metals together and expect them to stick without a plan,” says Assistant Professor Seungkyun Yim (Tohoku University). “We had to fully understand the in-situ alloying mechanism first.”

Now the team has successfully prototyped the world’s first full-scale automotive multi-material component, a suspension tower.

The research group intends to apply these findings to other metal combinations where similar issues with bonding need improvement.

If successful, multi-material 3D printing could have a big future in car manufacture.