Taming the Boost – 50 years of Porsche Turbo

Words: Kyle Cassidy

Porsche was an early adopter of turbocharging and it has been evolving the technology for over 50 years. We map out the German’s progress in the area while staying emissions legal.

Your starter for ten this month; what was the first production car with a turbocharger? If you said the 911 Turbo, wrong. GM got there first with the 1962 Oldsmobile Jetfire. While Yanks are famous for adding cubes to gain horses, Olds strapped a Garret turbo to its 3.5-litre V8 to crank up the output from 155hp to 215hp. And that is a turbo’s reason for being; extracting more power from an engine without adding cylinders and capacity.

A turbocharger uses the engine’s exhaust gases to spin a turbine, which in turn spins a compressor that forces more air into the combustion chamber to make a bigger bang and more power. It all sounds good, waste energy turned into added power but it’s not without problems. Chief among them is turbolag, the killer of throttle response. It takes time for the exhaust gases to flow sufficiently to spool the turbine and charge the intake. So there’s not much happening at low revs and then all of a sudden you get a big rush of power as the boost takes effect.

Porsche adopted turbo-tech first for its race cars. It decided on the turbo route for its 917 Can Am racers after testing a blown version of its 4.5-litre 12 cylinder. It made 625kW, 70kW more than a mammoth 8.0-litre flat 16 that Porsche also developed, while being lighter and more compact. It would harness the turbo for its 911 too, rolling out the first in 1974. And it’s been perfecting the tech ever since.

Race to road

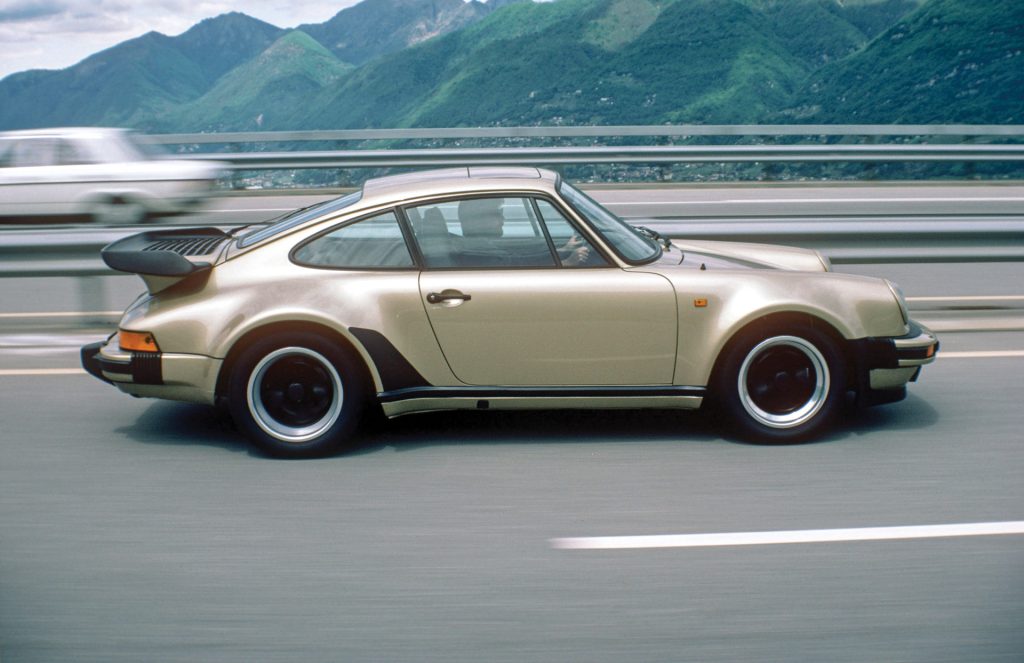

The original 911 Turbo was planned as a limited model but it proved popular and so they kept making them. The 930, as it was known, made 191kW and was the first production car with a boost pressure-controlled turbocharger. To avoid subjecting the engine to excess strain, the turbo’s boost pressure needs to be controlled. When the boost hits a certain limit, the excess pressure is bled off via a bypass valve known as the waste gate. This then made it possible to limit boost pressure and keep it at a constant level, making it more predictable but still rather laggy.

The intercooler and the whale tail

Compressing the air also makes it hotter, while cooler air is better for combustion and power. It helps tackle the issue of detonation too. Using an intercooler, a heat exchanger that cools the charged air before it enters the combustion chamber, Porsche managed to lower intake temperatures by 60 degrees in the second-gen 911 Turbo of 1978. Better combustion meant Porsche could fit a smaller turbo to help reduce lag. With a slight rise in capacity to 3.3 litres, the Turbo now made 212kW. The cooler was mounted on top of the engine, in the big ‘whale tail spoiler’. It remained there for all the air-cooled models, with power up to at 265kW for the 3.6-litre 964 Turbo.

Times two

Porsche’s quest to reduce turbolag in its 959 supercar saw it use two turbos in series, known as sequential turbocharging. It used a smaller turbo to get things pumping low in the engine range, while a larger, secondary turbo provided the boost at higher engine speeds.

However, the twin-turbo set-up changed when the 993 Turbo came along. Porsche went with a bi-turbo solution, using two equally-sized turbos, one for each cylinder bank. The two smaller turbos delivered 300kW of power with greatly improved response, compared with the old 964.

The twin-turbo set-up continued into the 996 generation but the move to water cooling brought particular advantages for the Turbo. Included were greatly improved cylinder head temperatures for more efficient consumption, and compliance with exhaust gas and noise laws.

Varying the flow

For the 997 turbo, Porsche introduced the variable geometry turbo (VGT). While this tech had been in use on diesel engines, the 997 was the first VGT designed for a petrol engine as it posed a greater technical challenge due to the higher exhaust temperatures. The VGT has adjustable vanes in the turbine housing that can alter the flow of exhaust gas onto the turbine. At low RPMs, the vanes are partially closed to restrict the flow, causing it to speed up and thus spin up the turbine faster, which minimises turbo lag. As engine speeds and the exhaust gas flow increases, they open to relieve the pressure build up. This produces stable boost pressures which leads to improved efficiency. The first 997 made 353kW, while the 992 developed 427kW.

Electric turbocharging

While the VGT solution served the Turbo well over the 997 to 992 generation of Turbos, for the latest 992.2, Porsche has adopted the e-turbo. First introduced on the new Carrera GTS, it’s part of a sports hybrid system. With a 400-volt electric architecture and small 1.9kWh lithium-ion battery, Porsche has added an electric motor in the dual-clutch transmission and another in the turbocharger itself.

This small motor resides on the shaft between the turbine and the compressor, and its main function is to spool the turbo instantly, eliminating lag and aiding response. Porsche says; “The technology enables responsiveness similar to that of a naturally aspirated engine. We couldn’t have realised the intended performance increase with conventional technology while also complying with future emissions legislation.”

With a single e-turbo, the 3.6-litre GTS delivers 398kW and torque of 610Nm with some help from the 40kW/150Nm motor incorporated into the eight-speed dual-clutch transmission (PDK).

The electric motor in the turbo also works as a generator, making up to 11kW of electricity. Said motor can be used to limit the speed of the turbine, so it doesn’t overboost, therefore doing away with the need for a wastegate. So once the boost pressure has been realised, the motor’s drag torque can be used to limit the turbine speed to 125,000rpm, and the drag generates electricity. This is either fed to the battery or to the motor in the trans.

The new Turbo S continues the evolution, the latest 911 range topper moving to the 3.6-litre engine of the GTS but with twin turbos. Compared with the outgoing model, it has a slightly smaller capacity, the VGT turbos have been replaced by a pair of e-turbos, and the GTS’s electric motor resides in the transmission. Unique for the Turbo are new intake and exhaust systems and revised engine internals. As to the turbos, while they have the same motor inside, they have smaller compressors and turbines compared with the GTS, which allows them to spin faster and make more boost. While the power has improved to a total of 523kW, torque remains at 800Nm, but the spread of peak pull is now much wider, developed from 2300 to 6000rpm. Because there are two e-turbos, they generate more power, so they are able to boost the peak output of the e-motor in the trans too.

While we are yet to drive the Turbo S, the GTS proved this set-up delivers excellent response, with not a whiff of turbo lag. That’s thanks in part to the combo of the in-trans motor providing instant torque and the turbos boosting so quickly.

The goal of this e-turbo evolution is to deliver more power while complying with ever-tighter emissions regulations. And so this latest Turbo engine is better able to maintain the ideal fuel/air mix at a wider range of engine speeds, particularly up high in the rev range. And this means the greatest engine efficiency while also allowing the catalytic converters to work more effectively.

Porsche already makes a Turbo model delivering 760kW without producing any powertrain emissions. But the take up of Taycan has cooled, particularly here in NZ, with just 10 sold YTD, and just one of those the Turbo. Meanwhile the 911 keeps ticking over, which is all the more reason for Porsche to continue to hone the flat six, improving performance while staying on the right side of emissions laws.