JLR cyber attack woes are ongoing

Words NZ Autocar | Images JLR

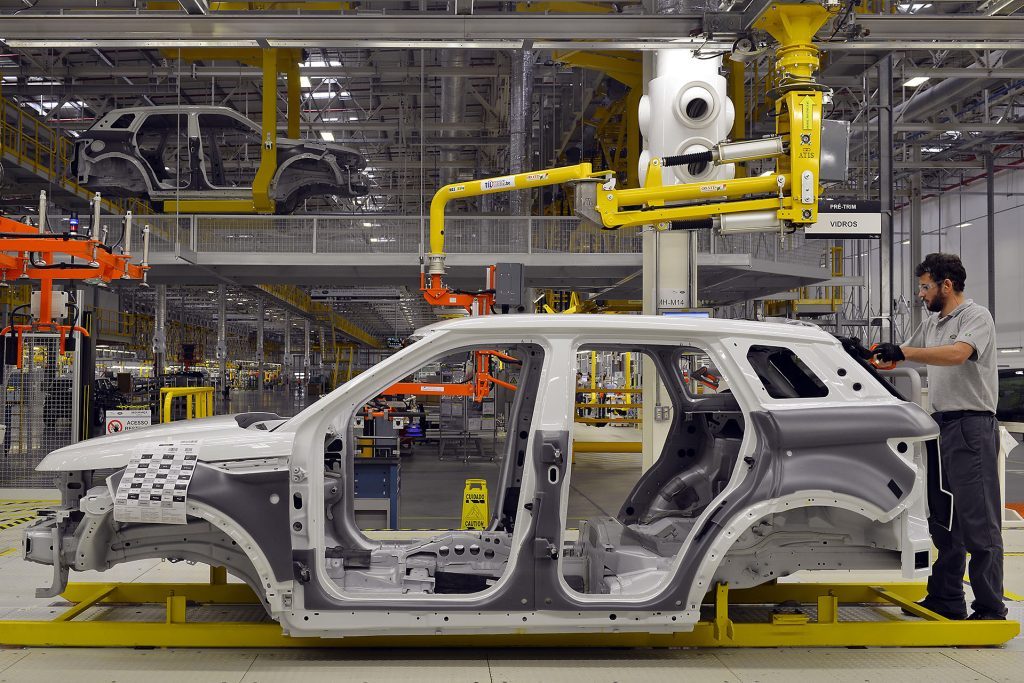

The UK production facilities of JLR remain out of action and are unlikely to restart until early October.

Meantime, Business Secretary Peter Kyle is set to meet with key suppliers, many of whom are at risk of bankruptcy.

JLR’s three main UK plants have been out of action since a major cyber attack in late August. The company had hoped for a full return to work on Sep 24th but that is evidently not going to happen.

The ongoing saga is putting immense pressure on the automaker’s supply chain. Some of the smaller firms may face closure for good unless the situation changes quickly.

JLR’s supply chain supports around 100,000 jobs in the UK. It includes many small- to medium-sized businesses that are dependent solely on the car maker.

Normally, JLR produces about 1000 cars a day at its three UK plants. It has told most of its 33,000 employees to stay at home as it works on a controlled restart of its operations.

Following the cyber attack, the firm’s IT team shut down its array of online systems, idling all the production lines. JLR has been working with “third‑party cybersecurity specialists and alongside law enforcement” to solve the IT issue.

While some data has been impacted, the precise nature of this has yet to be confirmed.

A spokesperson for cybersecurity firm Huntress said that the incident “highlights the critical vulnerability of modern manufacturing, where a single IT system attack can halt a multi-billion-pound physical production line”.

Whether or not JLR parts with cash to appease the hackers is unclear. But this incident will inevitably cause huge losses for the British giant. It had already seen a dip in quarterly sales for the first part of 2025 because of the implementation of US tariffs.

Huntress warned other manufacturers in the industry to design their systems so that core functions can continue even during an attack to reduce the financial and operational impact.

Brands must implement segmentation which involves creating digital firewalls between production networks and other business IT systems. This prevents a single point of failure from shuttering the entire operation.