Hybrid Tech Explainer

Here we try to explain the differences between the various types of hybrid because not all are created equal.

Vehicle manufacturers have long been fond of slapping badges on a car to denote a technical innovation. Turbo decals were once popular, DOHC too and ABS. It didn’t matter if one of these was on a Honda, Ford or Renault, for they meant the same thing. But now if a vehicle sports a hybrid badge, we know it has some form of electrification. But the term encompasses many different technical solutions.

All hybrids aim to do the same thing; reduce fuel consumption and emissions while maintaining (or in some cases improving) driveability by way of electrical assistance. What follows are some of the many ways this can be achieved.

What’s a mild hybrid?

A mild hybrid combines an internal combustion engine (ICE) with a small electric motor and battery. Generally speaking, it involves a 48v electrical architecture, which delivers an increased electrical output without requiring expensive isolation and cabling upgrades. This makes it a more cost-effective hybrid solution, while helping to reduce fuel consumption and emissions by around 5 – 10 per cent. Most mild hybrids use an electric generator (usually called a belt-integrated starter generator or ISG) which replaces the starter motor and alternator. The 48v system can also be used to power components previously driven by the engine. These ISGs can add torque to the engine at lower speeds via a belt driving the crank. It’s not usually sufficient to power the car alone but newer, more powerful systems can achieve some minimal electric motivation. The beefier electrical system can sustain longer engine-off periods when the idle/stop system kicks in, and enable smoother, more instantaneous restarts. Some also enable the engine to shut down when coasting. On over-run and during braking, the ISG acts as a generator to recharge the small 48v battery. Many European models now run mild hybrid set-ups, while some use the 48v system to run electric turbos.

It’s when makers use the hybrid badge on these mild set-ups that can cause confusion, like the Swift hybrid, and the Hilux hybrid; yes they are hybrids but not real hybrids.

Series, Parallel and Series-Parallel?

Upping the ante in terms of voltage, motor size and batteries, we get into ‘self-charging’ hybrid territory. This marketing term helps differentiate these from plug-in hybrids, and helps the general public understand that they don’t need to be charged from an external power source.

These series and parallel hybrids run higher voltage electrical systems that can use an electric motor to power the vehicle, while the use of the engine varies depending on the set-up.

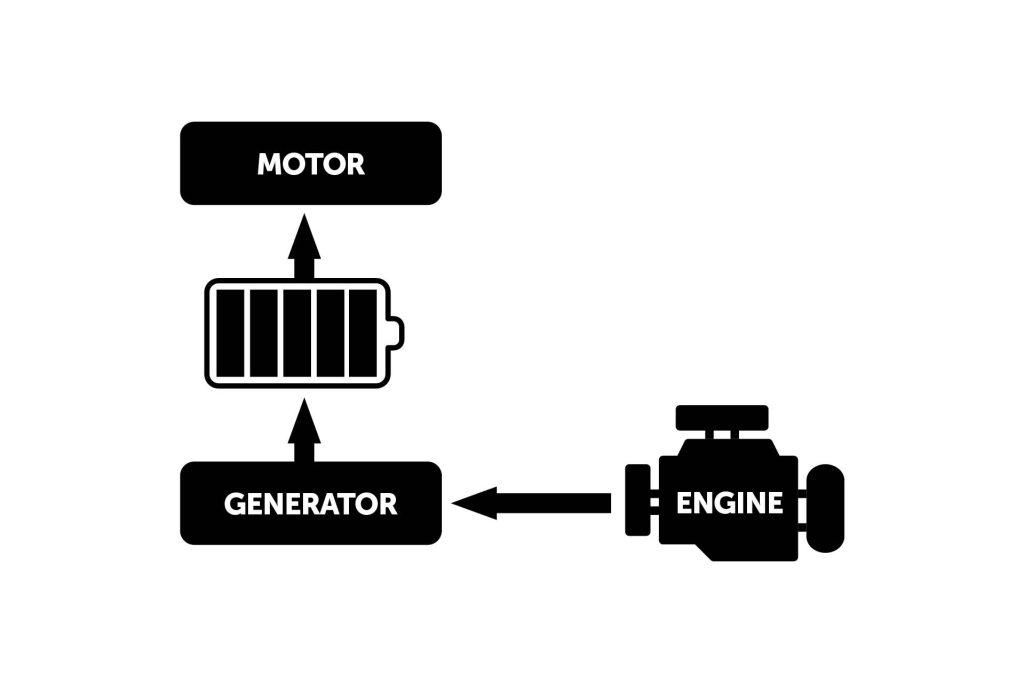

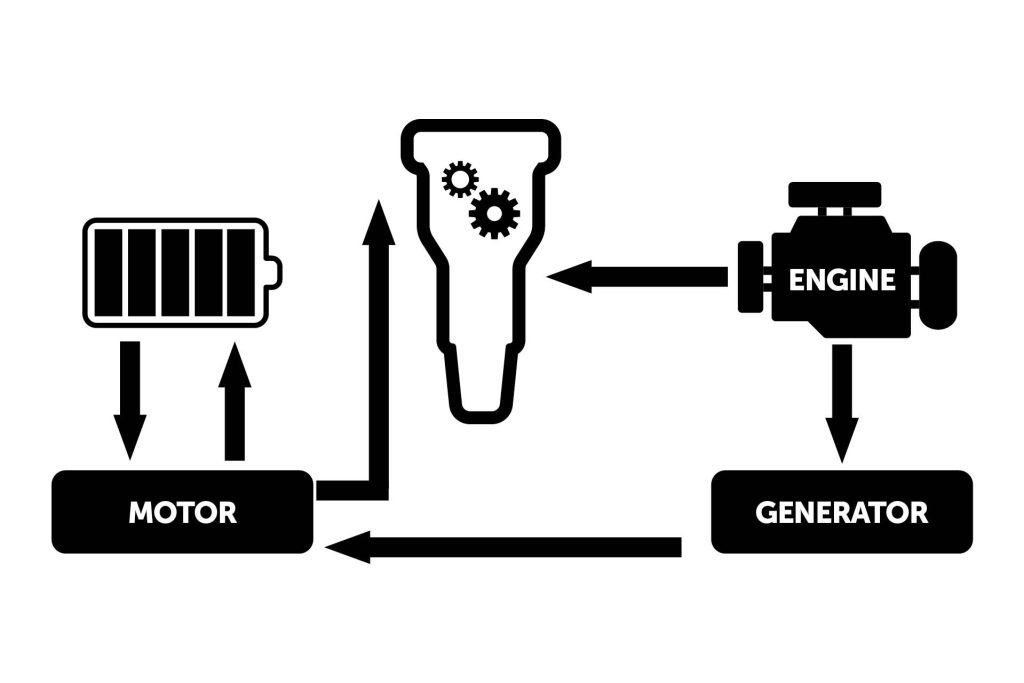

A series hybrid uses the electric motor alone to drive the vehicle, while the engine is used to turn a generator, making electricity to recharge the battery. A parallel hybrid uses the engine to primarily drive the vehicle with the motor assisting, whereas a series-parallel blends aspects of both.

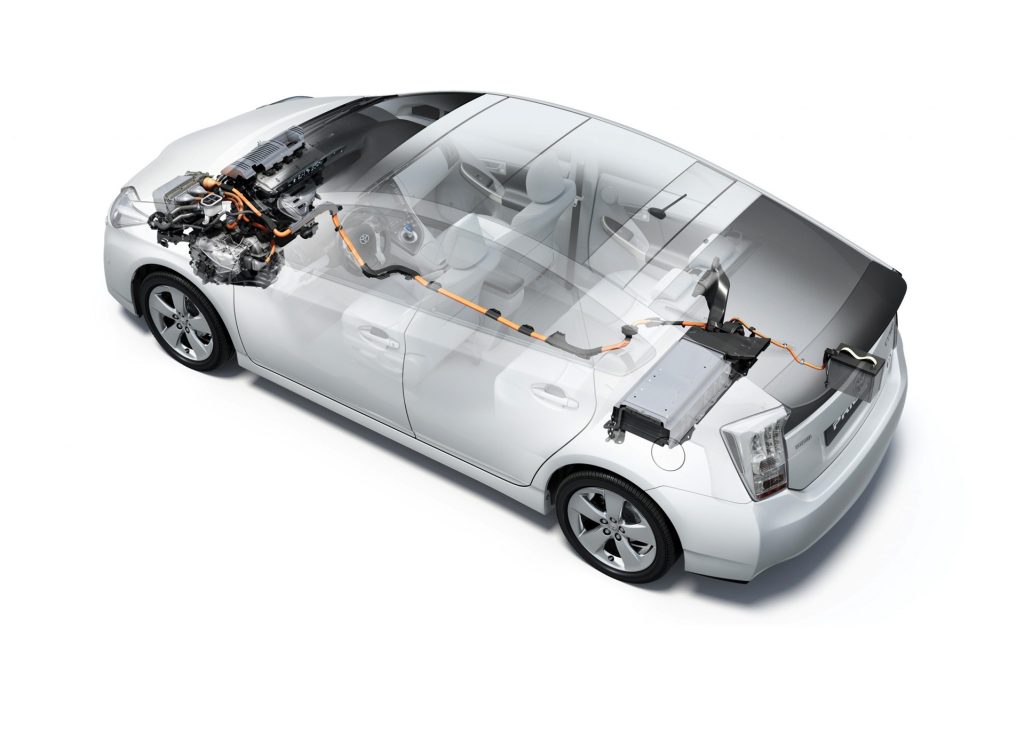

The power split hybrid

The most popular petrol electric set-up on the road is the Toyota hybrid synergy drive. It debuted in the 1997 Prius and the system has been constantly evolving since. This uses a lean burning petrol engine and two electric motor/generators connected via a planetary gearset. Via electronic control, the gear set or power splitter can blend the engine and motor power together providing the drive to the wheels. The gearset is referred to as an e-CVT as it allows for continuously adjustable gear ratios. By varying the input of the motor connected to the sun gear, it creates a variable ratio allowing the vehicle to accelerate, while keeping the engine in its most efficient operating band. And that’s the key to this hybrid set-up’s ultimate efficiency. This system is efficient at both low and higher speeds, though all hybrids produce their best economy in stop/start urban running.

Under a low load, the engine can switch off and the electric motors alone can power the car. When more power is needed, the engine output is seamlessly added to the mix. With this system, the engine can directly power the wheels with fixed gear ratios too.

This hybrid system uses a small battery pack (around 0.8 – 1.4kWh) which is recharged by the electric motor acting as a generator when decelerating, or when the engine alone is driving the wheels, the generators can recharge the battery.

Through constant evolution of the motors, controllers and drive logic, the Toyota hybrid system is the most efficient, and the latest fifth generation is optimised for all-electric running wherever possible. These improvements have also made it the best in terms of drivability, refinement and reliability.

Parallel hybrids

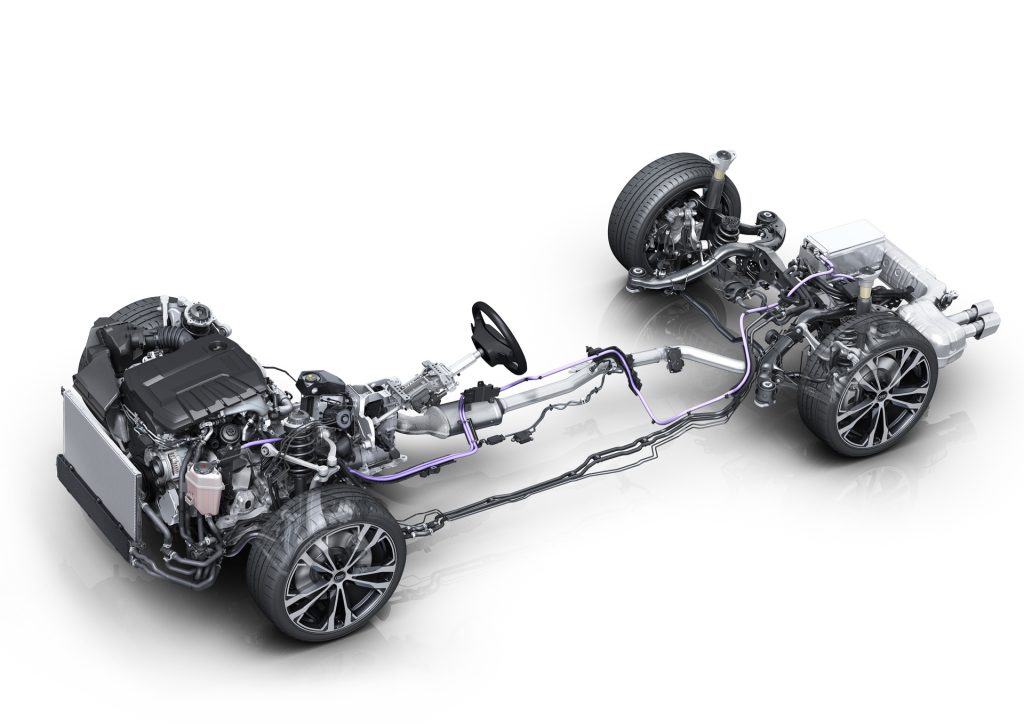

This is a more straightforward set-up, used by the likes of Hyundai and Kia. A parallel hybrid can use both the engine and the electric motors to drive the wheels, either separately, or together. The controller decides which is the most efficient power source for the occasion.

The Kia/Hyundai system uses an engine and a standard automatic transmission, but positioned between them is a motor. A clutch is used to either blend the two power sources together, or separate them. The motor can drive the vehicle at low speeds or when the engine isn’t needed to maintain speed. When more power is needed, the engine fires up, and the clutch engages its torque. This combined output is processed by the transmission. These set-ups don’t tend to be quite as smooth as the power split system when introducing the engine but they are improving.

Efficiency comes from the motor acting as a generator to both slow the vehicle and convert this energy into electricity for the battery. It’s then fed back to the motor to assist, reducing the engine’s consumption. However, it’s not as efficient as the power split device.

Series hybrid

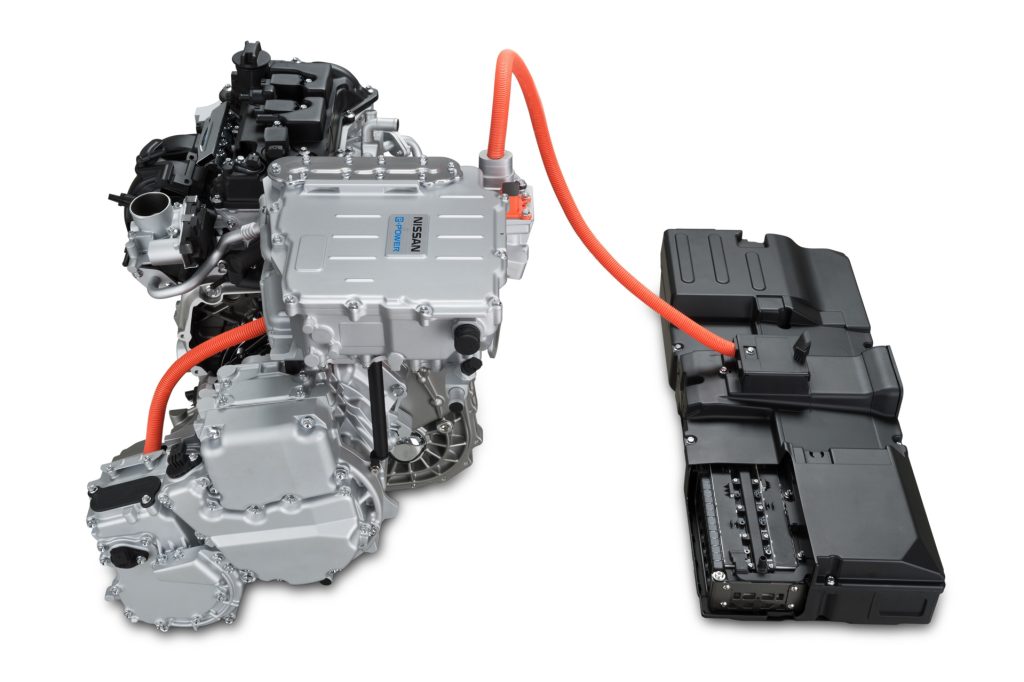

This uses electric drive as its only source of power, while the engine is used to run a generator to keep the battery charged. An example of this is the Nissan e-Power. It uses either one or two electric motors (the latter enabling AWD) to deliver an EV-like drive, where the torque is delivered freely and quickly. Without a multi-speed transmission, it’s smooth. The battery is a small 1.8kWh pack to keep weight and cost low. But it means the engine is often running to keep it sufficiently charged, and it’s constantly churning at highway speeds. This series hybrid does its best work at low speeds, so is more suited to urbanites stuck in traffic. Where a conventional ICE-powered vehicle is more fuel efficient during higher, constant-speed driving, it’s the opposite for the e-Power, where it returns higher consumption.

Nissan’s third-gen e-Power system has just debuted with optimised packaging of the electrical gubbins. It is said to be more compact, more powerful and efficient and quieter. A new engine is claimed to deliver a 15 per cent reduction in consumption at higher speeds, while it’s also much quieter.

A bit of everything

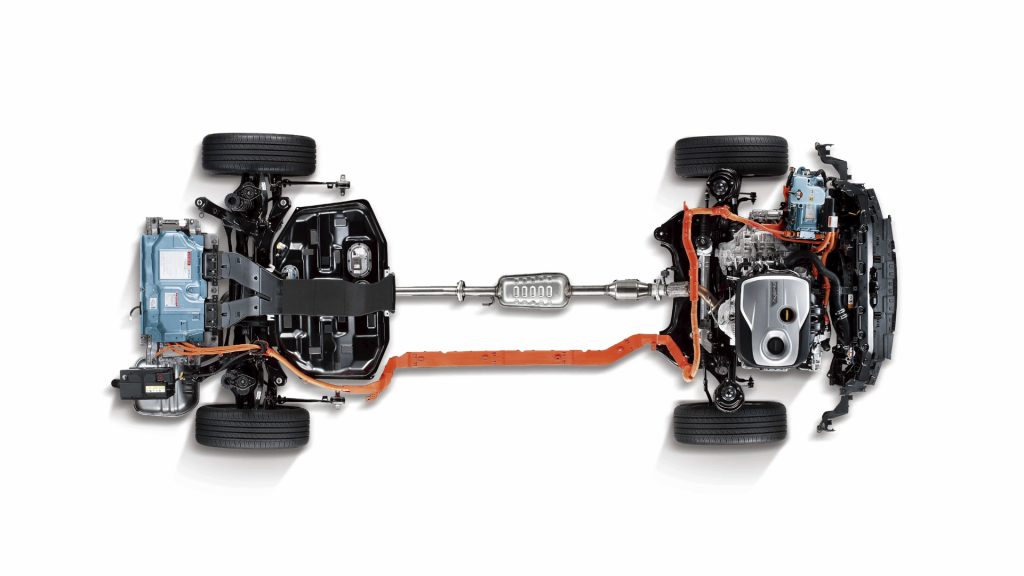

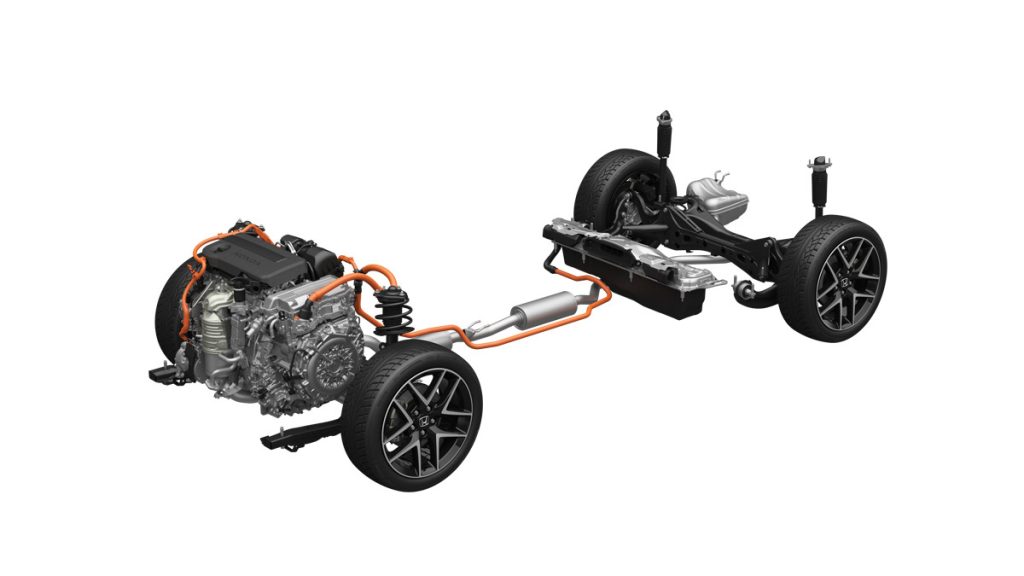

Honda was a hybrid pioneer, its Insight using a simple parallel system. It then moved to a power split type set-up, although it has recently set a new hybrid path with its e:HEV system. This works to maximise the best of each power source; electrics work better at slower, stop-start commuting, while the engine prefers higher-speed, constant-state driving.

The e:HEV uses two motors with the main traction motor sending its torque to the drive shaft, while regenerating under deceleration. The generator motor connects directly to the engine.

So around the city, the e:HEV powertrain operates as a series hybrid, the electric motor driving the wheels directly, while the engine runs the generator. At higher, more constant speeds, the engine’s output shaft is directly connected to the wheels via a lock-up clutch pack, as the engine is deemed to be the most efficient power source for this type of travel. The motor can also be supplied with electricity directly from the generator motor, if the system controller determines that as the most efficient drive. Crucially for the driver, e:HEV sorts all this out seamlessly and there is no way for them to manipulate the system, other than using the steering wheel mounted paddles to increase or reduce the effects of the regenerative braking.

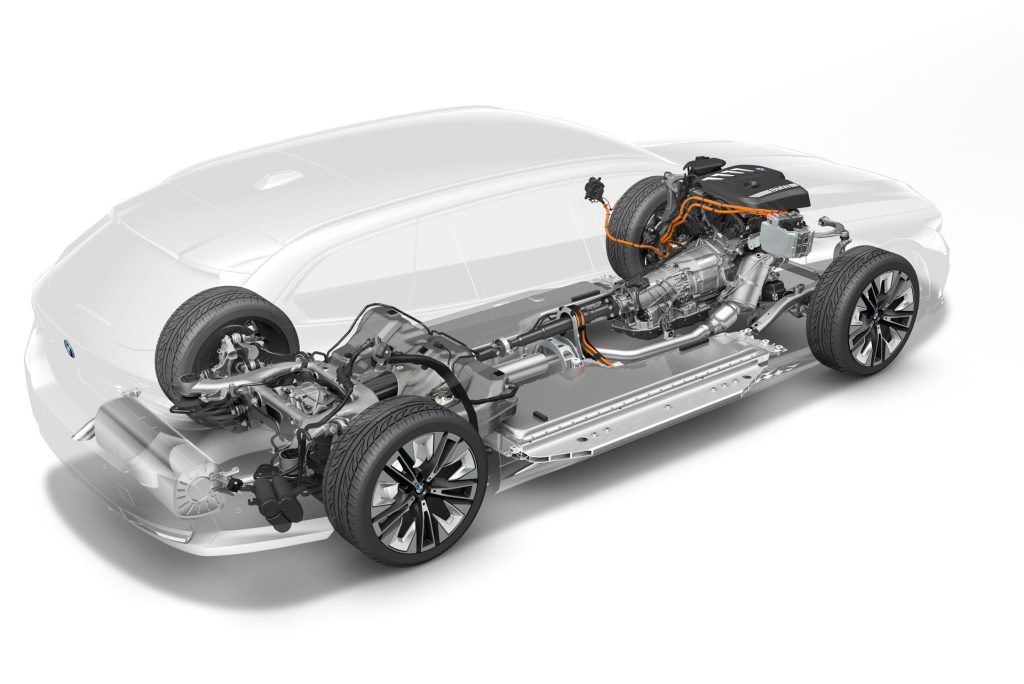

Plug-ins

A plug-in takes things a step further, adding a much larger battery with more voltage to drive a more powerful motor. The idea is that you can use the battery power to do the majority of your daily driving emissions free and recharge at night by plugging it in, to do it all again tomorrow. Early plug-ins had tiny EV ranges, but the latest ones, especially out of China, have larger batteries giving decent engine-off ranging. And with the current state of RUC rates, if you can maximise your EV miles, you’re getting a good deal with these PHEVs that can genuinely do a full day’s work around town without needing to fire the engine at all.

Once the battery charge has been depleted to a level that can no longer support pure EV mode, it defaults to HEV drive and the interplay of petrol and electric drive is much the same as the self-charging hybrids described above, depending on the system used. The BYD Shark 6, for instance, uses a series-type drive (although at certain highway speeds, the engine can add its power directly to the differential). The Sorento PHEV uses the same parallel system as the HEV version, albeit with a stronger electric motor. An advantage of the parallel system for PHEVs is that the motor’s output can be enhanced by the multi-speed transmission to help improve its efficiency.

Once in HEV mode, the PHEV’s powertrain is hauling around a lot of weight in that empty battery, affecting fuel consumption. And on that note, you’ll never achieve the claimed fuel consumption numbers of a PHEV in the real world. This is due to the anomalies of the testing procedure. The test is only 30 minutes long and covers 23.26km which allows most plug-ins to complete the majority of the trial on battery power alone, the engine only firing a few times during the procedure.

Some Euro manufacturers now include two fuel consumption figures for PHEVs; one tested with a full battery and one with a depleted battery. The M5 Touring for instance states consumption of 2.0L/100km, but when tested with an empty battery that number rises to 10.9L/100km, which is what you should expect when driving it in hybrid mode.

Hybrids add horsepower

Even the 911 is now a hybrid. The GTS uses ‘T-Hybrid’ tech to boost power, drivability and keep emissions in check. There’s a 40kW motor integrated into the eight-speed dual-clutch transmission, but it’s designed primarily to aid the engine’s output; there’s no electric-only drive from this set-up. It plumps up the torque curve early, filling the gap before the big turbo of the new 3.6-litre engine gets on boost. The hybrid electrics also help out there, as the turbo is electrically spooled, cutting lag further. The electrification of the 911 helps it comply with Euro emissions laws while also improving the engine’s response and the car’s overall drivability.

How can a motor also be a generator?

Regenerative braking is when the car’s motor is employed to both slow the vehicle and help recharge the battery. But how can this be? The ability of a motor to also function as a generator has something to do with Faraday’s Law of Induction. This states that a changing magnetic field can induce an electromotive force (voltage) in a conductor. Therefore, the same components and principles that convert electricity to motion (the motor function) can also convert motion to electricity (the generator function). So when you apply an electric current to a motor, its interaction with the magnetic field creates a force on the rotor, causing it to spin and produce mechanical energy. And so when the motor’s rotor is spun by an external mechanical force (in this case the wheels of the car in motion), it generates voltage. And so this is the process that converts mechanical energy into electrical energy.