E-fuels and their role in supporting electrification

Words/Images NZ Autocar

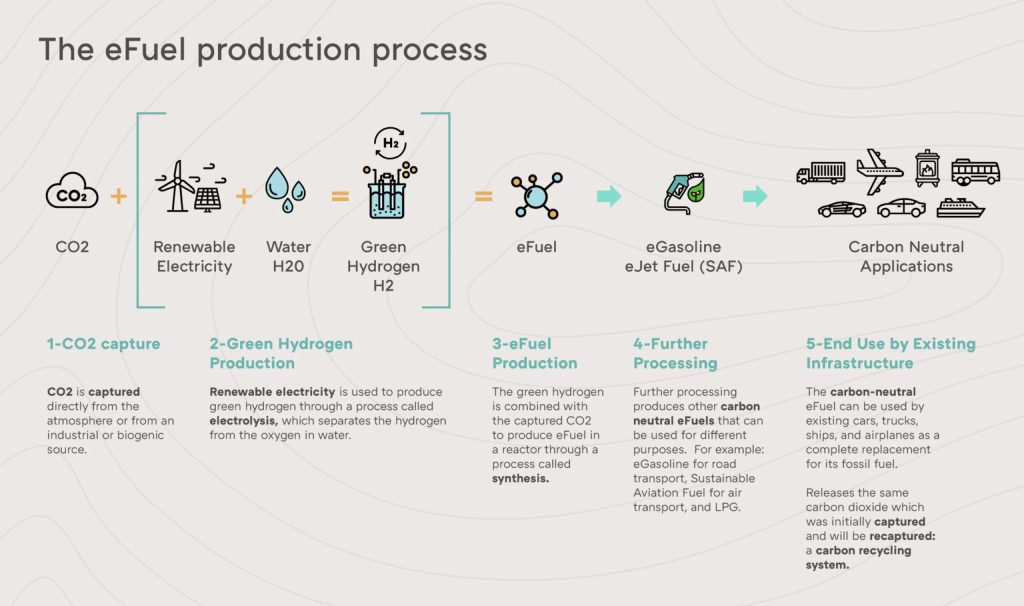

E-fuels, short for electrofuels, are synthetic fuels designed to power internal combustion engine (ICE) vehicles. They offer a more environmentally friendly alternative to traditional petrol and diesel.

E-fuels are produced using ‘green’ hydrogen and carbon, which is captured from the atmosphere or biomass waste. The combination of hydrogen and carbon dioxide results in a fuel that can power existing engines with minimal or no modification.

One of the key attractions of e-fuels is their potential to be carbon-neutral. Since the carbon dioxide used to produce them is captured from the air, their emissions are theoretically offset by the carbon removed during production. This has made them a point of interest for car manufacturers like Porsche and Ferrari. Both wish to prolong the life of their existing ICE powered cars.

Despite their promise, e-fuels face several challenges. While cleaner to produce than fossil fuels, they still emit pollutants when burned. Oxides of nitrogen (NOx), carbon monoxide (CO), and ammonia are harmful to both health and the environment. Studies have shown that e-fuels perform similarly to petrol in terms of NOx emissions and may emit more CO and ammonia.

Efficiency is another major concern. Vehicles powered by e-fuels are significantly less efficient than battery electric vehicles (BEVs). Research shows that e-fuels require four to six times more renewable electricity than BEVs to power a car the same distance. Much of the energy is lost during the conversion process from electricity to liquid fuel. The International Council on Clean Transportation (ICCT) reported that nearly half of the renewable electricity is lost when converting to e-fuels.

Production scalability and cost also hinder widespread adoption. E-fuels are currently expensive to produce and are only available in small quantities. It has been estimated that to run Europe’s fleet on e-fuels, energy production would need to increase by 150 per cent. That’s a major challenge given that only 40 per cent of the EU’s energy currently comes from renewable sources.

Nevertheless, several manufacturers see strategic value in e-fuels. Porsche has invested $NZ138m in a pilot e-fuel plant in Chile. It aims to produce around 130,000 litres annually. Another such facility is planned for Tasmania. The company sees e-fuels as a way to make the existing global fleet of 1.3 billion ICE vehicles more climate-friendly. Other automakers such as Ferrari, Ineos Automotive, Mazda, and Alpine support e-fuels. Car makers like Bentley and Volvo prefer focusing on full electrification.

In the policy arena, most governments have yet to incorporate e-fuels into their official decarbonisation plans, focusing heavily on the EV transition. However, a new report has criticised this strategy as overly narrow, citing EV infrastructure gaps and material shortages. The authors called for a broader approach, including addressing emissions from the existing petrol and diesel fleet.

Experts argue that e-fuels could serve a complementary role rather than a primary one in decarbonisation. While not suitable for mass vehicle electrification due to inefficiency and cost, they could be ideal for sectors where electrification is more difficult, like aviation and shipping. For example, Porsche’s e-fuel partner, Highly Innovative Fuels, is producing e-fuels at a plant in Chile powered by abundant local solar and wind energy, and a second plant is planned for Texas.

E-fuels then offer an intriguing path toward reducing emissions, especially for legacy combustion vehicles. While they are unlikely to replace EVs due to inefficiencies and environmental trade-offs, they may play a key role in niche applications and in regions with excess renewable energy. A balanced and honest assessment of transport decarbonisation strategies will likely require integrating both e-fuels and EVs, tailored to different sectors and geographic realities.