24M rethinks battery packs and boosts range by half

Words NZ Autocar | Images 24M

US firm 24M has thought inside the box, eliminating waste space within a battery and significantly increasing its usable capacity by 50 per cent. The new battery, which utilises known chemistry, is no bigger than an existing pack. And the firm says the new concept is virtually ready for production now.

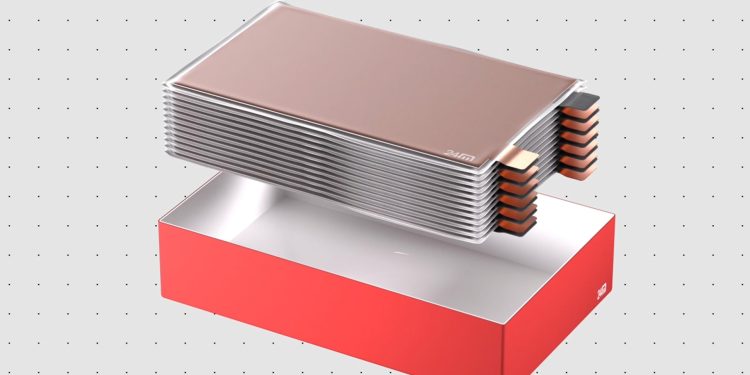

Massachusetts-based 24M Technologies details a new electrode-to-pack (ETOP) arrangement, which it claims offers “unmatched energy density”. It seals each electrode in a thin polymer film that is then integrated directly into the pack.

This new approach does away with individual cells. The company says the average lithium ion battery “features a large proportion of inactive, non-energy-carrying materials”, like metals and plastics comprising the structure of the battery itself.

By eliminating these supporting structures, 24M said manufacturers can “achieve the highest energy density” possible.

The best part is that ETOP can be used in NMC, LFP, NCA and sodium batteries.

The ETOP system allows a claimed 80 per cent of a battery’s volume to be made up of electrodes, compared with “the 30 per cent to 60 per cent of traditional battery packs”.

Therefore, the capacity of the battery can increase dramatically but occupy no more physical space. The makers also claim that the ETOP battery is cheaper to build.

It offers more flexibility in terms of the actual shape of the battery as well. For the polymer cells are more physically malleable, facilitating “virtually any shape” that suits the application and the space available.

24M said the technology is almost production ready. The first prototypes are complete and undergoing evaluation. It will be “ready for manufacturers to incorporate it quickly and cost-effectively into existing processes”.

The company adds that the relative similarity of its technology to today’s conventional battery structures means that it would require little extra investment for vehicle manufacturers to start using ETOP batteries.

The main cost is in building an ETOP-compatible production line but the method is “significantly less expensive than traditional cell-to-pack approaches”.

That’s because ETOP doesn’t need to make individual cells, avoiding the use of of cans and busbars.

They said: “We are encouraged by the strong OEM interest and look forward to delivering first prototypes” soon. The technology should be available in new cars by 2028.

Beyond automotive clients, 24M said it is also working with companies in the aviation, e-mobility and energy storage industries.